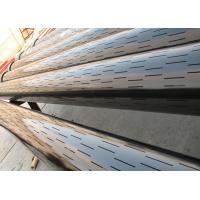

WWS Wire Wrapped Screen for Sand Control, Pipe Base Screen, 4 1/2''

N80

Tiptop manufactures sand control screens for Oil & Gas industry,

which include wire-wrapped screen, precision punched screen,

precise microspore composite screen, wire wrapped & bridge composed

pre-packed screens, etc, and slotted liners. We have the capacity

to design and manufacture as per your specific requirement. Please

contact us to order your WWS pipe.

Wire-wrapped screens retain the gravel in an annular ring between

the screen and the formation. Wire-wrapped screens have

substantially more inflow area than a slotted liner. The screen

consists of an outer jacket that is fabricated on special wrapping

machines that resemble a lathe. The shaped wire is simultaneously

wrapped and welded to longitudinal rods to form a single helical

slot with any desired width. The jacket is subsequently placed over

and welded at each end to a supporting pipe base (containing

drilled holes) to provide structural support.

The typical pipe-base screen fabrication consists of a grade 316L

stainless steel jacket placed over a N-80 pipe base; however, other

metals can be specified as required for site-specific applications.

The inflow area of screens varies from about 6 to 12% (or higher),

depending on the slot opening.

Features:

1. Key-stone shaped slot pattern, self-cleaning, not easy to block

and low risk to plugging.

2. Superior resistant to corrosion, long service life.

3. Optimized design for perforation, all welded structure, high

mechanical strength.

4. Min. 0.05mm slot width, which can satisfy requirement of the

most well completion requirements.

5. Various wire methods are available.

Specification

| API Base Pipe | Screen ID

(mm) | Screen OD

(mm) | Holes OD

(mm) | Holes Number per Feet | Rod Number

(Piece) | Screen Weight (kg/m) |

| Size (inch) | Weight (lb/ft) |

| 2 3/8 | 4.6 | 50.6 | 78.0 | 9.5 | 48 | 24 | 11.3 |

| 2 7/8 | 6.4 | 62.0 | 91.0 | 9.5 | 60 | 26 | 14.4 |

| 3 1/2 | 9.2 | 76.0 | 107.0 | 9.5 | 72 | 28 | 19.0 |

| 4 | 9.5 | 90.1 | 119.5 | 12.7 | 84 | 32 | 20.3 |

| 4 1/2 | 11.6 | 101.6 | 132.5 | 12.7 | 96 | 34 | 25.1 |

| 5 | 15.0 | 112.0 | 145.0 | 12.7 | 108 | 38 | 29.0 |

| 5 1/2 | 17.0 | 124.3 | 158.0 | 12.7 | 120 | 44 | 32.6 |

| 6 5/8 | 24.0 | 150.4 | 186.0 | 12.7 | 132 | 48 | 43.6 |

| 7 | 26.0 | 159.4 | 196.0 | 12.7 | 144 | 54 | 47.0 |

Notes:

(1) Wire and axial rod material: SS304, SS316L.

(2) Base Pipe: J55, N80, 13Cr, etc.

(3) Wire Wrapped Screens Length (FT): 6, 10, 20, 30, 40, etc.

(4) Wire adopted: pw90 X pw90